جميع المنتجات

-

محامل كروية سيراميك

-

608 محامل سيراميك

-

محامل سيراميك هجينة

-

محامل أسطوانية من السيراميك

-

محمل اقتحام السيراميك

-

تحمل انزلاق السيراميك

-

سيراميك إنشائي متقدم

-

كرة نيتريد السيليكون

-

كرة كربيد السيليكون

-

كرة سيراميك زركونيا

-

محامل كروية من كربيد السيليكون

-

نيتريد السيليكون واضعا الكرة

-

تحمل زركونيا السيراميك

-

الختم الميكانيكي

-

محامل كربيد السيليكون

-

روبرتاتتميز محاملها المصنوعة من السيراميك بالدقة العالية والنوعية الجيدة ورخيصة الثمن. لدينا تعاون لسنوات عديدة.

روبرتاتتميز محاملها المصنوعة من السيراميك بالدقة العالية والنوعية الجيدة ورخيصة الثمن. لدينا تعاون لسنوات عديدة. -

أولغا واينبرغهذه الشركة هي موردنا الموثوق والمهني لمحامل السيراميك لسنوات عديدة ، محامل السيراميك ، والتي تستخدم في المضخة لدينا جيدة في الجودة.

أولغا واينبرغهذه الشركة هي موردنا الموثوق والمهني لمحامل السيراميك لسنوات عديدة ، محامل السيراميك ، والتي تستخدم في المضخة لدينا جيدة في الجودة.

اتصل شخص :

Cooper wang

رقم الهاتف :

86 15801087509

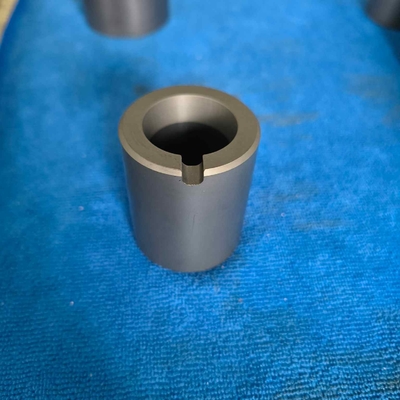

جلبة محمل انزلاقي سيراميك مخصصة للمضخات، 1650 درجة مئوية كحد أقصى

اتصل بي للحصول على عينات مجانية وكوبونات.

ال WhatsApp:0086 18588475571

wechat: 0086 18588475571

سكايب: sales10@aixton.com

إذا كان لديك أي قلق ، فنحن نقدم مساعدة عبر الإنترنت على مدار 24 ساعة.

xتفاصيل المنتج

| اسم | محمل الأكمام المخصصة للسيراميك | فئة | محمل انزلاق السيراميك |

|---|---|---|---|

| مقاس | مخصصة ، وفقا للرسومات | مادة | كربيد السيليكون/الزركونيا |

| طلب | مضخات | طَرد | الرغوة+مربع الكرتون |

| جودة | دقة عالية ، حياة طويلة ، مصل OEM | مواصفة | الحجم القياسي وتخصيصه |

| إبراز | جلبة محمل انزلاقي سيراميك مخصصة,جلبة محمل سيراميك ذات درجة حرارة عالية,محمل انزلاقي سيراميك للمضخة 1650 درجة مئوية,High-temperature ceramic bearing sleeve,Pump ceramic sliding bearing 1650°C |

||

يمكنك تحديد المنتجات التي تحتاجها والتواصل معنا في لوحة الرسائل.

منتوج وصف

كمّ السليكون كاربايد المخصص لزلق المحمل

تمثل محامل الزلق الخزفية فئة من المكونات عالية الأداء المصنعة بدقة من مواد خزفية متقدمة مثل نيتريد السيليكون (Si₃N₄) وكربيد السيليكون (SiC) والزركونيا (ZrO₂). يتم اختيار هذه المواد لخصائصها الاستثنائية، والتي تمكن المحامل من توفير متانة فائقة وموثوقية تشغيلية، متجاوزة بشكل كبير أداء محامل الصلب التقليدية في السيناريوهات الصعبة.

تم تصميمها لتلبية المتطلبات الصارمة للقطاعات الصناعية والسيارات والفضاء، تعمل محامل الزلق الخزفية بشكل استثنائي في الظروف المعاكسة - بما في ذلك التعرض للعوامل المسببة للتآكل ودرجات الحرارة القصوى وبيئات التآكل المكثفة - حيث تتدهور أو تفشل محامل المعادن التقليدية عادة.

المزايا الرئيسية

مقاومة التآكل الاستثنائية

قادرة على تحمل التعرض لوسائط شديدة العدوانية - بما في ذلك الأحماض القوية والقلويات والبيئات البحرية المالحة - هذه المحامل مناسبة تمامًا لمعدات المعالجة الكيميائية ومضخات مياه البحر وأنظمة الحفر البحرية، حيث تتآكل المعادن بسرعة.

احتكاك منخفض للغاية وتآكل ضئيل

تقلل السطح الأملس للغاية والصلب للغاية للسيراميك بشكل كبير من معاملات الاحتكاك، مما يؤدي إلى انخفاض استهلاك الطاقة وتقليل التآكل بشكل كبير. ينتج عن هذا عمر خدمة أطول يصل إلى 5-10 مرات مقارنة بمحامل الصلب أو سبائك المعادن التقليدية.

أداء فائق في درجات الحرارة العالية

مصممة للحفاظ على السلامة الهيكلية والموثوقية التشغيلية في درجات حرارة تصل إلى 1400 درجة مئوية، هذه المحامل مثالية لتطبيقات البيئات القاسية مثل التوربينات الغازية والمحركات النفاثة وأنظمة العادم والأفران الصناعية ذات درجة الحرارة العالية.

الكثافة المنخفضة والخصائص غير المغناطيسية

تقلل طبيعتها خفيفة الوزن من الكتلة الدورانية، مما يقلل من القصور الذاتي ويحسن الاستجابة الديناميكية في الأنظمة عالية السرعة. بالإضافة إلى ذلك، تمنع خصائصها غير المغناطيسية التداخل المغناطيسي، مما يجعلها ضرورية في تطبيقات مثل أجهزة الفضاء ومعدات التصوير بالرنين المغناطيسي والأجهزة الإلكترونية أو الطبية الحساسة الأخرى.

التطبيقات

يمكن استخدام المحامل الخزفية على نطاق واسع في الطيران والفضاء والملاحة والبترول والكيماويات والسيارات والمعدات الإلكترونية والمعادن والطاقة الكهربائية والمنسوجات والمضخات والأدوات الطبية والبحث العلمي والدفاع الوطني وغيرها من المجالات، وهي تطبيق للمواد الجديدة للمنتجات عالية التقنية.

الخصائص

| الخاصية | القيمة |

|---|---|

| أقصى درجة حرارة | تصل إلى 1650 درجة مئوية |

| كثافة منخفضة | 3.15-3.18 جم/سم3 |

| تمدد حراري منخفض | 4.0 (10-6/ درجة مئوية) |

| توصيل حراري عالي | 120 واط/م درجة مئوية |

| صلابة عالية | 2800 HV5 |

| معامل مرونة عالي | 410 جيجا باسكال |

| الاستقرار الكيميائي | مقاومة فائقة لتآكل الأحماض والقلويات (بما في ذلك حمض الهيدروفلوريك) |

مزايا المحامل الخزفية بالكامل مقارنة بمحامل الصلب

- يمكن استخدام المحامل الخزفية في درجات حرارة أعلى: يمكن للمواد الخزفية الحفاظ على خصائصها الميكانيكية بثبات في درجات الحرارة العالية.

- أكثر ملاءمة لتقلبات درجة الحرارة: معامل التمدد الحراري للسيراميك أصغر من معامل الفولاذ، مما يجعلها أقل تأثرًا بتغيرات درجة الحرارة.

- أداء أفضل مضاد للعض والالتصاق: يساعد معامل التمدد الحراري الأصغر على تقليل التشوه الحراري.

- يمكن أن تعمل بدون زيت: يتمتع السيراميك بخصائص التشحيم الذاتي ويمكنه استخدام الوسط للتزييت.

- مقاومة لتآكل الأحماض والقلويات والأملاح: مناسبة لبيئات التآكل الكيميائي.

- العزل الكهربائي وعدم وجود كهرباء ساكنة: السيراميك غير موصل ولن ينتج ظاهرة التآكل الحالية.

- يمكن استخدامه في البيئات المغناطيسية: السيراميك غير مغناطيسي، مما يمنع جزيئات المغناطيس من الالتصاق بأسطح المحمل.

مصنعنا وقدرات المعالجة

لدينا ثلاثة مصانع في الصين لتلبية احتياجات العملاء المختلفة، ومجهزة بآلات الضغط والتلبيد والمعالجة المتقدمة. تمتلك شركتنا أحد عشر براءة اختراع لطرازات المنفعة ولديها فريق محترف عالي الجودة لتوفير منتجات محامل مخصصة.

منذ عام 1982، تراكمت لدينا خبرة تزيد عن 40 عامًا في إنتاج المحامل الخزفية، مع التحسين المستمر لموادنا وتقنيات المعالجة والمعدات. لقد أصبحنا مؤسسة رائدة في سوق المحامل الخزفية ومنتجات المواد الخزفية في الصين.

لدينا خبرة واسعة في إنتاج محامل زلق كربيد السيليكون لمضخات التروس، بما في ذلك الإمدادات إلى ألمانيا فيت لسنوات عديدة.

مزايا المحمل لدينا

- عينات مجانية من المحامل متوفرة

- متوافقة مع معيار ISO

- المحامل في المخزون

- الطلبات الصغيرة مقبولة

- خدمة محامل OEM

- محامل مخصصة من رسومات أو عينات العميل

- أسعار المصنع التنافسية

الأسئلة المتداولة

س: من نحن؟

ج: نحن مصنع في بكين، الصين، لدينا خبرة تزيد عن 40 عامًا في إنتاج المحامل الخزفية، وقد أنشأنا علاقات تعاون مع العديد من الشركات المحلية والأجنبية.

س: كيف يمكننا ضمان الجودة؟

ج: ننتج عينات قبل الإنتاج الضخم، ونتبع بدقة متطلبات العملاء، ونجري عمليات تفتيش دقيقة، ونستخدم عبوات مزدوجة (رغوة وكرتون) لضمان جودة المنتج.

س: ماذا يمكنك أن تشتري منا؟

ج: محامل كروية ذات أخدود عميق من السيراميك، محامل كروية ذات تلامس زاوي، محامل كروية خزفية هجينة، محامل خطية، وكرات خزفية مختلفة.

س: لماذا يجب أن تشتري منا؟

ج: نحن شركة متكاملة مع ثلاثة مصانع، ومعدات إنتاج وفحص حديثة، ونقدم أوقات تسليم أفضل وجودة منتج أفضل.

س: ما الخدمات التي يمكننا تقديمها؟

ج: منتجات عالية الجودة، وخدمات مخصصة بالكامل، وعينات لتأكيد العميل.

نرحب باستفسارك

نتعاون مع موردي المواد الخام لضمان الجودة والتسعير المستقرين. عند الضرورة، يمكننا إنتاج المواد الخام بأنفسنا. نلتزم باحتياجات العملاء كإرشاد لنا، ونسعى جاهدين لتوفير منتجات عالية الجودة وخدمة ما بعد البيع، وخلق قيمة للعملاء كشركائهم. مرحبًا بك لمناقشة التعاون!

المنتجات الموصى بها