-

محامل كروية سيراميك

-

608 محامل سيراميك

-

محامل سيراميك هجينة

-

محامل أسطوانية من السيراميك

-

محمل اقتحام السيراميك

-

تحمل انزلاق السيراميك

-

سيراميك إنشائي متقدم

-

كرة نيتريد السيليكون

-

كرة كربيد السيليكون

-

كرة سيراميك زركونيا

-

محامل كروية من كربيد السيليكون

-

نيتريد السيليكون واضعا الكرة

-

تحمل زركونيا السيراميك

-

الختم الميكانيكي

-

محامل كربيد السيليكون

-

روبرتاتتميز محاملها المصنوعة من السيراميك بالدقة العالية والنوعية الجيدة ورخيصة الثمن. لدينا تعاون لسنوات عديدة.

روبرتاتتميز محاملها المصنوعة من السيراميك بالدقة العالية والنوعية الجيدة ورخيصة الثمن. لدينا تعاون لسنوات عديدة. -

أولغا واينبرغهذه الشركة هي موردنا الموثوق والمهني لمحامل السيراميك لسنوات عديدة ، محامل السيراميك ، والتي تستخدم في المضخة لدينا جيدة في الجودة.

أولغا واينبرغهذه الشركة هي موردنا الموثوق والمهني لمحامل السيراميك لسنوات عديدة ، محامل السيراميك ، والتي تستخدم في المضخة لدينا جيدة في الجودة.

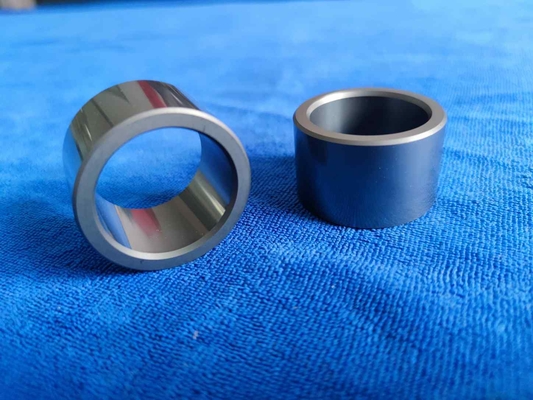

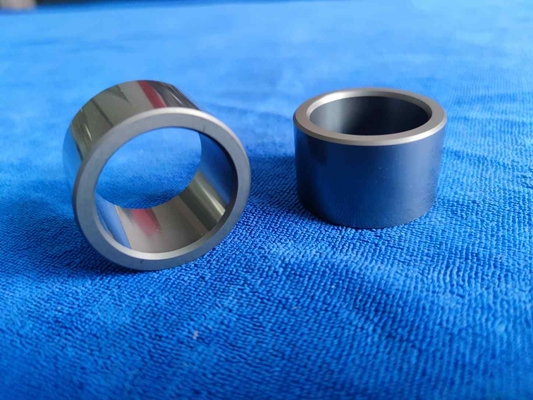

Corrosion Resistant Ceramic Sliding Bearing for Industrial Automotive and Aerospace Applications

| Place of Origin | China |

|---|---|

| اسم العلامة التجارية | CSQ |

| إصدار الشهادات | FDA,REACH,ROHS,ISO9001,ISO14001,ISO45001 |

| Model Number | customized products |

| Minimum Order Quantity | 20-50 pcs |

| الأسعار | negotiable |

| Packaging Details | Foam+carton box |

| Delivery Time | 20-45 work days |

| Payment Terms | T/T |

| Supply Ability | 2000pcs per month |

اتصل بي للحصول على عينات مجانية وكوبونات.

ال WhatsApp:0086 18588475571

wechat: 0086 18588475571

سكايب: sales10@aixton.com

إذا كان لديك أي قلق ، فنحن نقدم مساعدة عبر الإنترنت على مدار 24 ساعة.

x| Name | Customized ceramic sliding sleeve bearing | Category | Ceramic sliding bearing |

|---|---|---|---|

| Material | Pressureless sintered silicon carbide | Size | Customized,according to the drawings |

| Application | Pumps | Package | Foam+carton box |

| Quality | High precision, Long life, OEM serive | Specification | Standard size and customized |

| Attribute | Value |

|---|---|

| Name | Customized ceramic sliding sleeve bearing |

| Category | Ceramic sliding bearing |

| Material | Pressureless sintered silicon carbide |

| Size | Customized, according to the drawings |

| Application | Pumps |

| Package | Foam + carton box |

| Quality | High precision, Long life, OEM service |

| Specification | Standard size and customized |

Ceramic sliding bearings are advanced bearing technology used in industrial, automotive, and aerospace applications. Constructed using ceramic materials like silicon nitride, silicon carbide or zirconia, they offer superior performance compared to traditional steel bearings.

- Corrosion Resistance: Highly resistant to harsh chemicals and environments, ideal for chemical processing or marine applications.

- Reduced Friction: Smoother, harder ceramic surfaces minimize friction and wear, improving performance and lifespan.

- High Temperature Tolerance: Withstands extreme temperatures without degradation, perfect for engine components and industrial machinery.

Ceramic bearings are widely used in aviation, aerospace, navigation, petroleum, chemical, automotive, electronic equipment, metallurgy, electric power, textile, pump, medical instruments, scientific research, and defense industries.

| Max Temperature | Up to 1650℃ |

| Density | 3.15-3.18 g/cm³ |

| Thermal Expansion | 4.0 (10-6/℃) |

| Thermal Conductivity | 120 W/m°K |

| Hardness | 2800 HV5 |

| Elastic Modulus | 410GPa |

| Chemical Stability | Superior resistance to acid and alkali corrosion (including hydrofluoric acid) |

- Higher temperature stability maintaining mechanical properties

- Better performance with temperature fluctuations due to lower thermal expansion

- Improved anti-bite and anti-stuck performance

- Can operate without lubrication in high vacuum environments

- Resistant to acid, alkali and salt corrosion

- Electrical insulation with no static electricity

- Non-magnetic properties prevent abrasive particle adhesion

With three factories in China, we utilize advanced pressing, sintering and processing machines to meet diverse customer needs. Our company (ZXSQ/CSQ) holds eleven invention patents and maintains a professional team dedicated to producing high-quality ceramic bearing products.

Since 1982, we've accumulated over 40 years of experience in ceramic bearing research, development, and production. We've evolved into a leading enterprise in China's ceramic bearing and material market, supplying SSiC sliding bearings to international clients like Germany's Witte.

- Free sample bearings available

- ISO Standard compliant production

- Bearings available in stock

- Small order quantities accepted

- OEM bearing services

- Customized bearings from customer drawings or samples

- Competitive factory pricing

We are a factory in Beijing, China with over 40 years of ceramic bearing production experience, maintaining cooperative relations with domestic and international companies.

We produce samples before mass production, strictly follow customer requirements, conduct precise inspections, and use foam+carton double packaging to ensure product quality.

Ceramic deep groove ball bearings, angular contact ball bearings, hybrid ceramic ball bearings, linear bearings, and various ceramic balls.

As an industry and trade integrated company with three factories and modern equipment, we offer better delivery times and product quality.

High quality products, full customization according to user needs, and sample confirmation services.

We cooperate with raw material suppliers to ensure stable quality and pricing. With our production technology, we can even produce raw materials when necessary. Customer demand drives our commitment to quality products and after-sales service. We welcome discussions about potential cooperation!